PROJECT INTENT

The construction of Recypark will significantly contribute to the development of the circular economy and the fulfillment of the principles of the waste management hierarchy. Innovative technology will transform 72,000 tonnes of municipal and similar waste annually into new raw materials. While this waste has so far been landfilled or used for energy recovery, the new technology will enable its conversion into methanol—highly sought after in industry—and vitrified slag, which can be used in the construction sector.

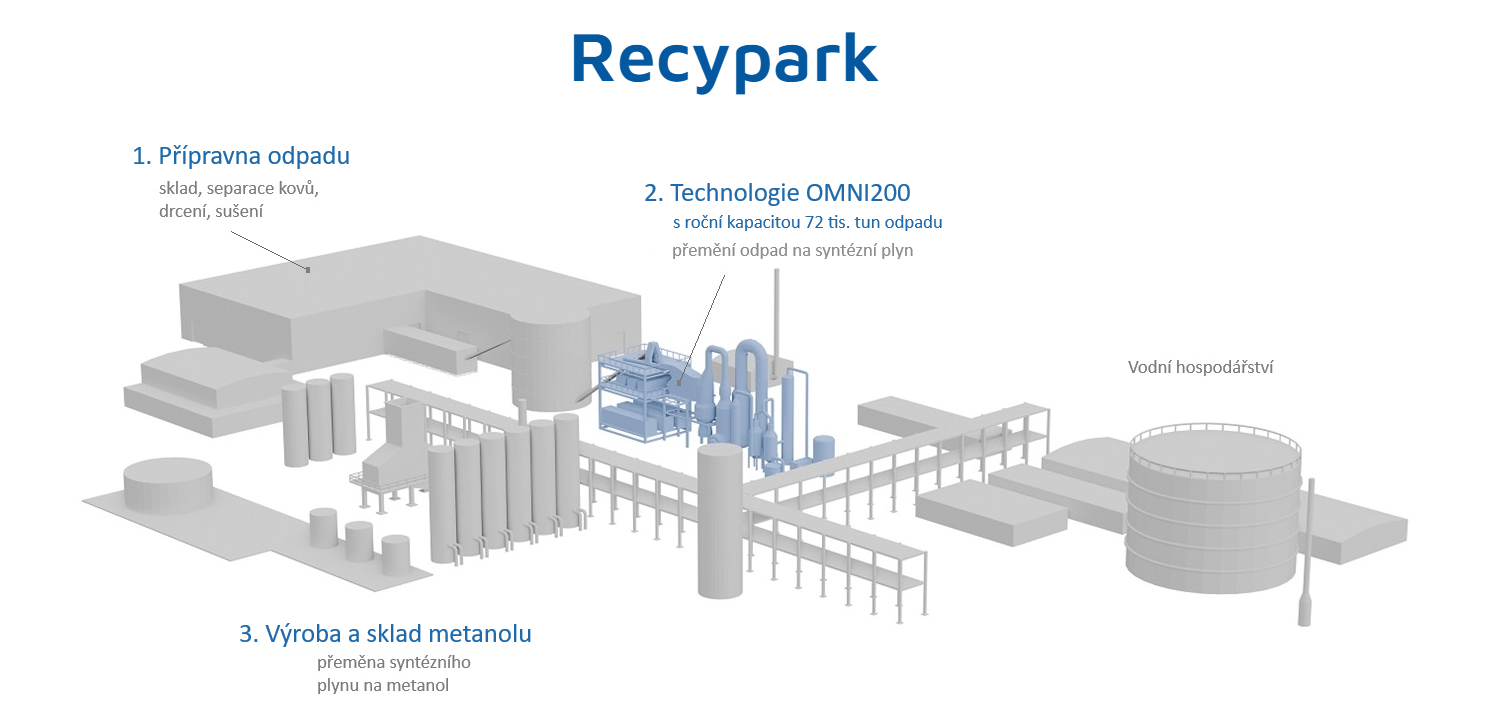

Recypark will be built on a 5.5-hectare site.

It will consist of three key sections:

- Waste preparation unit, where ferrous and non-ferrous metals will be separated. The remaining waste will then be shredded and dried. This pre-treated material will be stored in a silo as feedstock for the next phase.

- OMNI200 technology, which will convert 72,000 tonnes of treated waste annually into synthesis gas (syngas) and vitrified slag, usable in construction.

- Distillation column, where catalytic conversion of syngas into methanol will take place—a product in high demand in the chemical industry.

The facility will also include a water management system ensuring the treatment and adjustment of process water. Thanks to a recirculation system, daily consumption of newly added water will be reduced to a minimum—just 27 m³. This water will be sourced from collected rainwater and groundwater. This approach ensures environmentally responsible water management without excessive strain on water resources.